R&W PDM (Production Data Management) System

R&W PDM is a system for gathering, storing and evaluating production data in an industrial environment and supports intelligent manufacturing.

Components of the R&W PDM System

In order to gather and evaluate production data of different systems, several components are required that communicate with each other. R&W uses Industrial Ethernet, which is widely used for this purpose by now.

R&W DBConnect

R&W’s DBConnect devices takes the processing of production data directly to the production line. The devices gather and process the data where it is generated. Gathering and retrieving of production data in a database directly in the automation. R&W offers three different components for accessing a database. The control systems send SQL commands directly to the database via the DBConnect devices.

In this way, the full range of functions of the database can be used. The database commands are administered in the control system, the place where the data accrues. R&W provides tools for designing and testing the database commands. The commands can then be converted into Siemens-S7 function blocks, for instance. R&W provides suitable software libraries for communication with the database. The system is optimized for Siemens S7, but can also be combined with other control systems.

SQL database for quick access to production data

The data is stored in an SQL database. The R&W DBConnect system supports databases such as MS SQL Server, MySQL and other systems. The database structure is then individually compiled according to its system configuration and thus optimized for fast access. Databases at different locations can be synchronized via the Internet. In this way, the data can be viewed and compared company-wide. Furthermore, the database can be used as an interface to other systems (ERP, MES...).

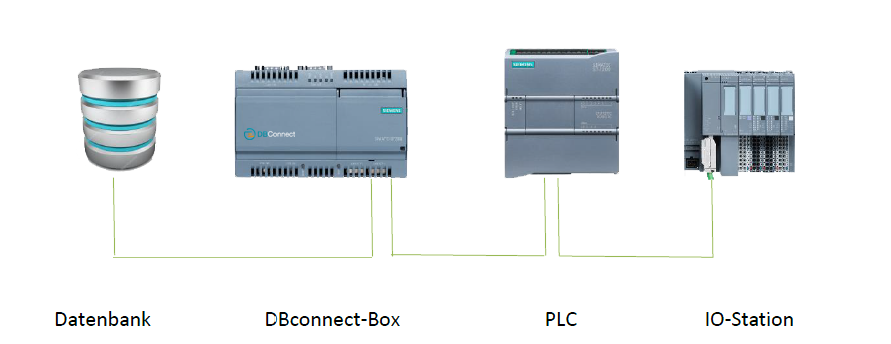

DBConnect box

The R&W DBConnect box is the interface between the controller and the database. The controller communicates with the DBConnect box via simple telegrams. The DBConnect box adapts the different data formats of the controller and database systems and ensures smooth communication.

The DBConnect box can be connected to various types of databases. The parameters are set via the integrated web server. Two independent Ethernet interfaces provide a separation between the network of the field level and the network of the database level.

Typical structure:

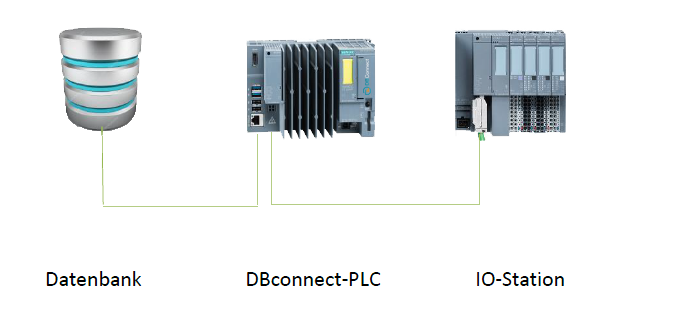

DBConnect plc

With the DBConnect plc, the controller and the connector to the database are integrated in one device. With the powerful S7-1500 Software Controller CPU1515SP, complete production lines can be controlled and at the same time production data can be gathered.

The controller accesses to the remote database via the onboard Ethernet interface. As with the DBConnect box, the SQL commands can be created and tested with the R&W DBConnect tool.

Typical structure:

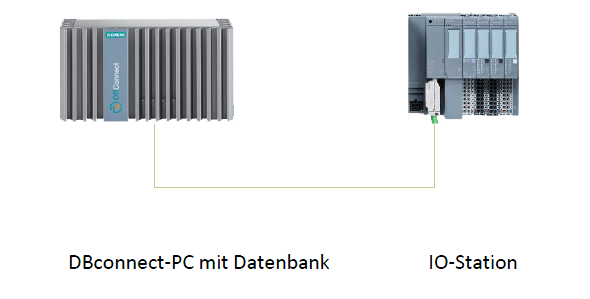

DBConnect pc

With the DBConnect pc, controller, connector and database are integrated in one device. With the powerful S7-1500 software controller installed on a Nanobox PC, complete production systems can be controlled and production data recorded simultaneously.

The controller accesses to the internal database via the integrated modules. As with the DBConnect box, the SQL commands can be created and tested with the R&W DBConnect tool.

Typical structure:

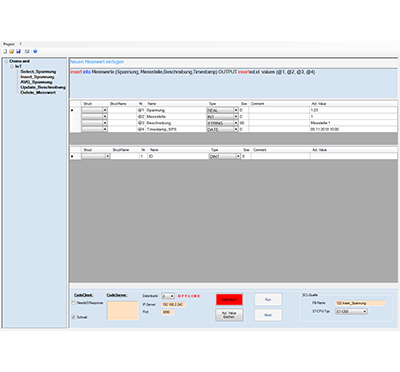

DBConnect tool

The Config tool is used to set up and test the database connections. It displays an overview of all connections.

After a successful test, the tool can be used to generate the individual commands in the form of SCL sources. These can then be translated into corresponding function modules using the Simatic programming environment.

Evaluation of production data

R&W creates customer-specific evaluation software for you to display and analyze the recorded production data.

WEB server

The WEB server allows access to the stored data. It is a stand-alone application that can be installed on a separate PC as well as on the DBConnect pc. The WEB server accesses the data in the database and provides it in web pages. In addition to evaluating the data, the web server can also be used to enter required values.

Visualization

The visualization is done by web pages. Therefore, no special software is necessary on the display devices, only a web browser has to be installed. The web pages are created individually for the customer and his data available in the database. The data are displayed in tabular and graphical form. In addition to conventional PCs, smartphones and visualisation computers available on the systems are also suitable for access.

Special pages optimized for access with smartphones allow a quick overview of the most important key figures of production on the road. Production and downtimes as well as the efficiency of the system are visible at a glance. Access to the web pages can take place within the company's network or via remote access.

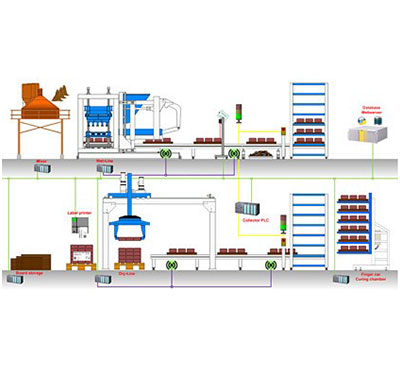

PAVE-IT - The R&W PDM System in a Concrete Plant

From the concrete mix to the pallet

Pave-IT gathers production data in the concrete plant. In order to ensure a closed flow of information from the wet to the dry side, identifiable base plates are used. The technology is based on an RFID chip in the base plate that allows the plate to be uniquely identified along its path in production.

A PLC collects the quality-relevant data from the controllers of the mixing plant, wet side, dry side, quality measuring devices, etc. Using the chip number, the information in a database can be assigned to the corresponding base plates.

Thus, a wide variety of information such as production data, quality characteristics, etc. can be assigned to each base plate - thus to a stone layer produced on it. The combination with an R&W height control system allows a continuous quality management, because for each layer all data are available and traceable at any time up to the stacking unit.

Quality fluctuations are immediately displayed on the dry side and can be used there for automatic sorting. The number of cycle times and service intervals of the base plates can also be documented.

By using the R&W height control system systems and Pave-IT, the complaint rate can be significantly reduced.

Current production data increase efficiency

Intelligently related to each other, the production data and their evaluations are made available to users throughout the entire company via a WEB server in a timely and objective manner.

R&W PDM provides up-to-date and reliable data from all production areas. On this basis, the right decisions can be made at company management level.

Do you have a question or a request?

Please feel free to use our contact form. We will get back to you as soon as possible.

R&W Industrieautomation GmbH

Weidenstr. 1

57627 Hachenburg

Fon: +49 (0)2662 941434

Mail: info(at)r-u-w.de

Web: www.r-u-w.de